E-MBR membrane

0₫

e-MBR is a micro bio-reactor membrane

Integrated and compact design, the module height can reach 5m, which saves a lot of space compared to traditional MBR membrane technology on the market

The membrane frame is designed simply and is simple to disassemble when it needs to be replaced.

Hotline 1: 0969 867 924

Hotline 2: 0969 867 925

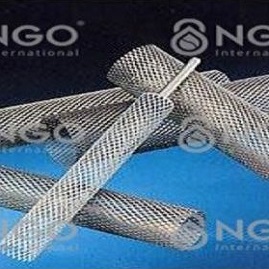

EMBR modular flat membrane, different from soft membrane and hollow fiber membrane, inherits the characteristics of stable operation of flat membrane, designs the membrane unit into a smaller area, forms a water production summary flow channel through self-locking interconnection between membrane elements, and can be assembled into a more dexterous modular membrane module without hose connection. Not only has the characteristics of flexible and convenient assembly and molding, connection of connecting pipes, stacking of multiple groups, manual handling and site installation, but also can overcome the limitations of site size and water level height and meet the maximum stacking rate of membrane modules.

EMBR modular flat film, using E PTFE / PVDF polyfluoro composite film, is permanently hydrophilic, has extremely low pressure difference, acid and alkali resistance, oxidation resistance and high temperature resistance, and has ultra-high strength. The base plate is made of glass fiber composite material and is deeply hot-melt welded, suitable for long-term underwater operation. Therefore, the service life of EMBR modular flat membrane products is much longer than that of MBR membranes.

Made by: Sevoo Shanghai, China

Outstanding features of e-MBR membrane:

- Integrated and compact design, the module height can reach 5m, which saves a lot of space compared to traditional MBR membrane technology on the market

- Critical flux>700L.m2.day – membrane material is super hydrophilic

- Transmembrane Pressure (TMP) <= 4kPa, that has the lowest transmembrane pressure on the market today

- Save more aeration energy, only 4-5L/m2.min

- Chemical washing membrane only 2-3 L/m3

- Exceptionally optimal investment costs. Committed to the BEST MARKET COST.

Some pictures of e-MBR membrane:

|

Model |

eMBR100 | EMBR-C |

eMBR-C*N |

| Type | e-MBR50 | ||

| Number | 100 | C (customization, multiples of 10) | C*N (Number of component layers) |

| Area(m2) | 50 | C*0.5 | C*0.5*N |

| Size (mm) | 1150×636×560 | (C*10+150)× 636 × 560 | (C*10+150)×636×(560*N) |

| Specs of water production interface | DN25×2个 | ||

| Specs of aeration interface | DN50×2个 | ||

| Specs of air diffusion interface | DN50×2个 | ||

| Aeration intensity(L/min) | 300 | C*3 | C*N*2 |

| Capability(m3/d) | 10~30 | C*(0.1~0.3) | C* N(01~0.3) |

| Membrane box weight(kg) | 60 | C*0.5+10 | (C*0.5+10)*N |

| Aeration box weight ( kg) | 14 | C*0.04+10 | |

| Frame materal | Anticorrosive material | ||

7 patents cover the products.

Produced in accordance with the ISO 9001 Standard

Be the first to review “E-MBR membrane” Cancel reply

Related products

Filtration equipment

Filtration equipment

Filtration equipment

Electro Coagulation Equipment

Flotation equipment

Block equipment

Electro Ionization Equipment

Electrolytic equipment

Reviews

There are no reviews yet.