Ultrafiltration System

0₫

UF Ultrafiltration system is capable of removing up to 99.9% of bacteria and viruses

Hotline 1: 0969 867 924

Hotline 2: 0969 867 925

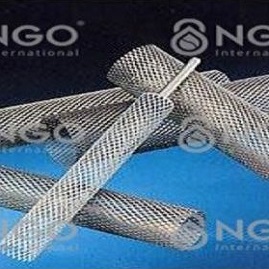

Ultrafiltration system, also known as UF ultrafiltration system, uses a spiral H-PVDF polymer hollow fiber membrane. Membrane pore sizes range from 0.01 to 0.1 microns, typically 0.03 microns. Ultrafiltration columns are based on the principle of pressure filtration to separate particulate matter from dissolved compounds using ultrafine membranes.

UF systems are suitable for the following areas:

- Drinking water

- Raw materials for the production process, which require high requirements on water quality, are often used as pre-filters for RO in the following systems: Bottled water, beverage, food; Ultra-pure water for electronics, semiconductor industry…; Desalination system from salt water, brackish water…

- Recirculating water treatment (wastewater recycling)

UF processing capabilities:

- Membrane size 0.03 micro can remove over 99.9% bacteria & viruses.

- Make pure water with turbidity less than 0.1 NTU

- Output sludge density index SDI <3

Advantages of UF system:

- Finished water quality (turbidity, SDI) remains stable regardless of input water quality disturbances.

- Very high water recovery: 95%.

- UF can directly replace the RO pre-filtration system (with relatively clean input water), providing higher quality RO pre-filtered water. Thereby reducing the requirement for RO membrane washing, reducing chemicals and wastewater, and increasing membrane life.

- Compact, space saving compared to traditional filter systems.

- Easy to customize, can add and remove modules directly when there is a change in flow or when replacing, maintaining and repairing without stopping the system.

- Low transmembrane pressure (1-6 bar) so less power consumption, optimal operating costs.

- Wide operating pH range 6-9 (2-12 for membrane washing).

- The filter is chlorine resistant.

- The operation and washing system is highly automated, reducing labor costs.

Equipment description

UF is typically modular in design consisting of hollow membrane fibers encapsulated within a PVC cover. These modules are positioned vertically on a slider that forms a system rack with pre-connected piping for easy transport and on-site installation. Depending on the current capacity and spare capacity, add or subtract the appropriate number of modules.

91 / 5.000 Kết quả dịch Kết quả bản dịch UF is typically designed as a modular structure consisting of hollow membrane fibers encapsulated within a PVC sheath. These modules are positioned vertically on a slider that forms the system rack with pre-connected piping for easy transport and on-site installation. Depending on the current capacity and standby power, add or subtract the appropriate number of modules.

Be the first to review “Ultrafiltration System” Cancel reply

Related products

Electro Coagulation Equipment

Flotation equipment

Electro Ionization Equipment

Filtration equipment

Filtration equipment

Block equipment

Filtration equipment

Flotation equipment

Z- Filter

Z- Filter

Reviews

There are no reviews yet.